MTService is a locally owned, Georgetown-based HVAC company with a reputation built on integrity and years of outstanding customer service. Mirek works closely with you, the customer, to ensure your complete satisfaction with our heating and cooling repairs and installations. We participate in coursework to stay atop of the latest industry trends. You deserve to feel comfortable knowing that a trustworthy and knowledgeable person is in your home.

Affordable A/C Repair…Tips

Our experts explain how to repair the most common causes of central air conditioning service failures.

Our experts shows you easy DIY solutions for the most common central air conditioning repairs. You’ll be up and running sooner and will save the expense of a service call.

By the DIY experts of The Family Handyman Magazine

Overview: Central air conditioner service failures and solutions

When central air conditioning service fails during a heat spell, you may have to wait days for an HVAC repair technician to show up, and you’ll probably pay at least several hundred for the repair. But if you’re comfortable working around electricity and are willing to spend about $50 on parts, you can probably repair your air conditioning service yourself in about two hours and save about $225 on parts markup and labor.

We talked to local HVAC repair technicians to get their best do-it-yourself AC repair and maintenance tips. These tips will help you with the most common “low cooling” and “no cooling” problems. You’ll need an inexpensive multimeter, a voltage sniffer, an assortment of screwdrivers and a socket set.

If these AC repairs don’t work, at least you’ve covered the most common failures, and your service guy can concentrate on finding the more elusive problem. Plus, with the new parts, you’ll likely add years of breakdown-free air conditioning. Here’s how to start.

Make sure the problem isn’t the furnace

Set your thermostat to AC mode and lower the temperature setting. If the furnace fan kicks in, the problem isn’t in the furnace. If the fan doesn’t run, try resetting the furnace circuit breaker. If the fan still won’t start, call a pro — the fixes shown here won’t work.

Next, check the outside condensing unit. The compressor (which sounds like a refrigerator) and fan should be running. If not, follow the troubleshooting and repair procedures shown here.

Caution: Turn Off the Power

Turn off the A/C and furnace breakers in the main electrical panel before pulling the outdoor disconnect or removing the condensing unit’s access panel. Then use a voltage tester on the wires coming into the contactor to make sure the power is really off.

Buy parts

The contactor (relay) and start/run capacitor(s) (see illustration below) fail most often and are inexpensive. So it’s a safe bet to buy and install those parts right away, especially if your air conditioning service unit is older than five years. The condenser fan motor can also fail, but it runs about $150 — hold off buying that unless you’re sure that’s the culprit.

To buy replacement parts, find the nameplate on the condensing unit (not your furnace). Jot down the make, model and serial number (or take a photo). Get the parts at an appliance store, furnace dealer or online.

Anatomy of a Central Air Conditioner

Central air condition service systems consist of two major components: a condensing unit that sits outside your house, and the evaporator coil (often referred to as an A-coil) that sits in the plenum of your furnace or air handler. The refrigerant in the A-coil picks up the heat from your home and moves it to the outdoor condensing unit. The condensing unit fan blows outside air through the condensing coil to remove the heat. The condensing unit houses the three parts replaceable by a DIYer: the contactor, the start/run capacitor(s) and the condenser fan motor. The condensing unit also houses the compressor, but only a pro can replace that. The A-coil has no parts that can be serviced by a DIYer.

Start with the easy fixes

Photo 1: Shut off the power

Open the electrical box next to the condensing unit and pull the disconnect block straight out. Check inside the box with a voltage sniffer to make sure the power is really off.

If you’re getting little or no cold air, check these three things first. Make sure all the registers in the house are wide open. Then be sure the furnace filter is clean. Then go outside and clean off the condenser coils (Photo 2). If several registers were closed or the filter was clogged, the reduced airflow could have caused the evaporator coil to ice up and stop cooling your home. If you’ve changed the filter and opened all the registers and you’re still not getting airflow at the registers, deice the A-coil. Move the thermostat mode switch from “Cooling” to “Off” and move the fan switch from “Auto” to “On.” Let the blower run for at least 30 minutes or until there’s good airflow at the registers. Then turn the AC back on to test it. If it works for the next 12 hours, you’ve solved the problem.

If the condenser coils are clogged, the compressor can overheat and shut down. You’ll experience intermittent periods of minimal cooling, followed by no cooling. Even if you’re “sure” the condenser coils are clean, clean them again. Turn off the power. Flip the air conditioning service and furnace circuit breakers in your main electrical panel to the “Off” position. Next, turn off the power switch right at the furnace or air handler. Then yank the disconnect block (Photo 1) and clean the condenser coils (Photo 2). If the air conditioning service still doesn’t work properly after you’ve cleaned the condenser coils, installed a new filter and opened all the supply vents, proceed with the following repairs.

Test the fuses

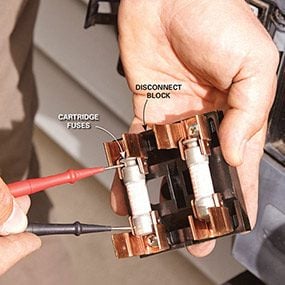

Photo 3: Check the fuses in the disconnnect block

Set your multimeter to the lowest Ohms scale and touch the red and black leads to opposite ends of each fuse. If you get a numerical reading, the fuse is good. But a zero, a minus symbol or an infinity symbol (∞) indicates a blown fuse.

Many disconnect blocks contain two cartridge fuses. Check them before you proceed with repairs (Photo 3). A blown fuse is a sign of a failing part inside the condensing unit. So don’t just replace it and think you’ve solved the problem. Instead, replace the parts we show here. Then install new fuses and fire up the unit. If it blows again, call a pro—you’ve got more serious issues.

Inspect the inside of the access panel

Photo 4: Discharging a dual start/run capacitor

Remove the capacitor from the retaining bracket. Then touch an insulated screwdriver between the HERM (or “H”) terminal and the COMMON (or “C”) terminal. Do the same between the FAN (or “F”) terminal and the “C” terminal. On single-mode capacitors, just make a short between the two terminals.

Follow the electrical conduit from the house — that’s where you’ll find the access panel. With the power off, remove and store the access-panel retaining screws and remove the panel. Before you replace any parts, check for rodents’ nests or evidence of chewing on wires and electrical connectors.

If you find broken wires or chewed insulation and can safely handle electrical repairs, discharge the capacitor first (Photo 4). Then repair the wires and clean out the nest. Otherwise, call a pro.

Replace the start/run capacitor(s)

Photo 5: Install the new capacitor

Slide the new capacitor into the retaining bracket and tighten the bracket screw. Secure the wires with a zip tie.

All air conditioning service units have at least one capacitor. The capacitor stores electricity and releases it during compressor and condenser fan startup to give both motors an extra jolt of power. And it smooths out voltage fluctuations to protect the compressor and condenser fan motor from damage.

Capacitors can degrade slowly, providing less startup power over time. Or they can fail in an instant. Gradual capacitor failure can go unnoticed for a long time, stressing the compressor and condenser fan motor windings, resulting in their early failure. Since capacitors are cheap, it pays to proactively replace yours about every five years.

Replacing a capacitor is easy. Just take a photo of the wires before disconnecting anything (you may need a reference later on). Then discharge the stored energy in the old capacitor (Photo 4). Use needle-nose pliers to pluck one wire at a time from the old capacitor and snap it onto the corresponding tab of the new capacitor. The female crimp connectors should snap tightly onto the capacitor tabs. Wiggle each connector to see if it’s tight. If it’s not, remove the connector and bend the rounded edges of it so it makes a tighter fit on the tab. When you’ve swapped all the wires, secure the new capacitor (Photo 5).

WARNING: Discharge the capacitor before disconnecting wires or removing it from its bracket.

Replace the contactor

Photo 6: Swap out the contactor

Yank a connector off the old contactor and move it to the same location on the new part. Tighten the connectors where needed. Then secure the new contactor in the condensing unit.

A contactor is a $25 mechanical relay that uses low-voltage power from the thermostat to switch 220-volt high-amperage current to the compressor and condenser fan. AC contactors can wear out and are at the top of the list of common air conditioning service failures. Even if your contactor is working, it pays to replace it every five years or so. Unscrew the old contactor before removing the wires. Then move the wires to the new unit (photo 6).

Test your repairs

Photo 7: Replace the fan motor

Mark the blade to show which side is up. Loosen the fan blade setscrew and carefully pull it off the motor shaft. Then swap in the new motor. Route the motor wires through the old conduit and secure with zip ties where necessary. Don’t skip the zip ties or the blade could cut the wires.

Reinstall the access panel and disconnect block. Turn on the circuit breaker and furnace switch. Then set the thermostat to a lower temperature and wait for the AC to start (see “Be Patient at Startup,” below). The compressor should run and the condenser fan should spin. If the compressor starts but the fan doesn’t, the fan motor is most likely shot. Shut off the power and remove the screws around the condenser cover. Lift the cover and remove the fan blade and motor (photo 7). Reinstall the blade and secure the cover. Then repower the unit and see if the fan starts. If it doesn’t, you’ve given it your best shot—it’s time to call a pro.

Be Patient at Startup

AC units and thermostats have built-in delay features when they’re shut down and then repowered. The delay can be as long as 10 minutes. And, if you’ve subscribed to an energy-saving device from your local power utility, the unit can take even longer to reset. If you’ve installed the parts shown and reinstalled the disconnect block, repowered the circuit breaker, turned on the switch at the furnace, moved the thermostat to AC mode and lowered the temperature below the indoor temperature, and the unit doesn’t fire up after 30 minutes, it’s time to call a pro.

Required Tools for this Project

Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration.

- Adjustable wrench

- Drill/driver – cordless

- Insulated screwdrivers (2)

- Needle-nose pliers

- Nut driver

- Socket/ratchet set

- Voltage tester

You’ll also need a multimeter.

Required Materials for this Project

Avoid last-minute shopping trips by having all your materials ready ahead of time. Here’s a list.

- Capacitor

- Compressed air

- Condenser fan motor

- Contactor

- Fuses